![]() 'Prod.' tab

'Prod.' tab

Max. number of data blocks:

You can set a maximum for the number of data blocks. If a pallet exceeds this number, then the rest of the data is discarded. It is necessary to do this as otherwise the reinforcement machine may crash if it has to handle too much data.

Produce bottom longitudinal bars layer 1:

Produce bottom longitudinal bars layer 2:

Produce bottom longitudinal bars layer 3:

Produce bottom secondary bars:

Produce top longitudinal bars layer 1:

Produce top longitudinal bars layer 2:

Produce top secondary bars:

Produce secondary stirrups:

The relevant bars are produced or omitted. The "bottom" longitudinal bars layers 1 and 2 and the "bottom" secondary bars apply for walls and slab elements. Longitudinal bars layer 3 and all 2 "top" bars apply only to the hollow plank units.

Produce arc secondary bars:

Produce arc-shaped stirrups:

The relevant bars are omitted or produced as developed bars or arc bars (Unitechnik interface 5.1 and higher).

When MWS is enabled, the program creates the stirrup cage data based on the Transfer stirrup cages to welding facilities option in the Meshes/stirrups configuration entry. In this case, the Produce arc secondary bars setting has no effect.

![]() 'Filter' tab

'Filter' tab

Producible cross bar diameters:

Enter the diameters that the reinforcement machine can handle.

You can enter one or more values. Example: 6, or 6,8,10, .

Producible longitudinal+secondary bar diameters:

Enter the diameters that the reinforcement machine can handle.

You can enter one or more values. Example: 6, or 6,8,10,12,14, .

Non-producible cross bar lengths:

You can enter cross bar lengths that you do not wish produced. With this feature you can exclude certain bars from production e.g., prefabricated cross bars.

You can enter one or more values. Example: 0-0.199 or 0-0.199, 2.485,

Non-producible longitudinal+secondary bar lengths:

You can enter lengths that you do not wish produced.

You can enter one or more values. Example: 0-0.199 or 0-0.199, 2.485,

![]() 'Miscellaneous' tab

'Miscellaneous' tab

Insertion angle for wall / slab robot:

You can set separate values for walls and slabs for the angle of the bars placed by robot. Bars that cannot be placed can be bundled.

Grab offset for double grab:

At the moment this parameter is not used.

Transfer spacer type:

You can set whether and for which bars spacers are transferred.

Relative secondary bar end position:

This parameter affects the storage position of the bundled bars at the pallet end.

0: the bars are placed within or adjoining the end of the pallet.

>0: the bars project over the pallet end, depending on the value specified.

<0: the bars are placed within the pallet, depending on the value specified.

Transfer cross shutter positions:

Some machines require the positions of the cross shutters to be transferred in addition to the bar data. This applies to the KT reinforcement machine, for example.

Code number for bars placed manually

Parameter for mesh welding system.

![]() 'Bundling' and 'Bundling2' tabs

'Bundling' and 'Bundling2' tabs

Bars that cannot be placed due to the insertion angle of the robot.

Bottom cross bars... layer 1, layer 2, layers 1+2

Top ... cross bars layer 1, cross bars layer 2, cross bars, reinforcement

Secondary bars not in span direction

Secondary bars in span direction

Free bars

Bundle:

You can specify here whether and if yes, where the relevant bars are set down as bundled. "Bundling" means that the relevant bars are placed at one (particular) coordinate location. These bars are then placed by hand.

No: bars that cannot be placed are not bundled.

At corner: the bars are set down at a panel corner.

Free space: the program sets the bars down in any free space near the panel (at the wall panels for fitted panels or slab elements). If there is no space available, then the program uses the "at corner" function.

Disabled: applicable to free bars only. This criterion does not apply to free bars (attached reinforcement); in other words, only free bars are not bundled.

Produce in leaf II:

No: bars in leaf II that cannot be placed are not produced.

With leaf I: bars in leaf II that cannot be placed are transferred to leaf I.

With leaf II: bars in wall leaf II that cannot be placed are produced as normal.

Disabled: only for free bars (attached reinforcement).

Storage height of the bars above the pallet:

The specified height is transferred as a Z coordinate. This value cannot however be used by all reinforcement machine systems.

Set insertion angle to 0 degrees:

Normally the actual angle of the bundled bars is transferred.

Select "Set insertion angle to 0 degrees - Yes " to recalculate the insertion angle and set it to 0 degrees. This setting is required on some machines (Filzmoser) so that the robot can place 2 bars at once (with a double grab).

However, some machines need a real insertion angle (not equal to 0 degrees) so that they can recognize any unplaceable bars.

![]() 'Storage' tab

'Storage' tab

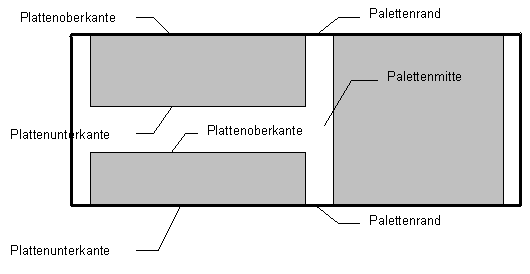

Storing the bars at the panel corner:

Applicable to the At corner setting, you can specify the exact place for setting down the bars and have the option of entering a further displacement.

Edge/BL: the setting down point is the panel corner nearest the pallet edge (for fitted panels). If both panel corners are equidistant, then the setting down point is the bottom corner of the panel (for standard panels).

BL: the setting down point is always the bottom edge of the panel, irrespective of the state of the panel (fitted panel).

TL: the setting down point is always the top edge of the panel, irrespective of the state of the panel (fitted panel).

Center/BL: the setting down point is the corner nearest the pallet center measured in the Y direction (for fitted panels). If both panel corners are equidistant, then the setting down point is the bottom corner of the panel (for standard panels).

Edge/TL: the setting down point is the panel corner nearest the pallet edge (for fitted panels). If both panel corners are equidistant, then the setting down point is the top corner of the panel (for standard panels).

Center/TL: the setting down point is the corner nearest the pallet center measured in the Y direction (for fitted panels). If both panel corners are equidistant, then the setting down point is the top corner of the panel (for standard panels).

Displacement of bars in

x direction (+/- = right/left):

y direction (+/- = in/out of panel):

Normally the program sets bundled bars down at the edge of the panel. You can apply a displacement for this setting down point. The next parameter, the minimum offset to the panel edge, has a higher priority than the current parameter. The value must always be complied with as it ensures that the setting down point cannot be outside the pallet.

x direction: displacement of the setting down point in the x direction. A negative value means a displacement to the left, a positive value a displacement to the right. This allows e.g., bundled bars to be moved to the cross shutter.

y direction: displacement of the setting down point in the y direction. A negative value means a displacement into the panel, a positive value a displacement out of the panel, irrespective of the joint edges.

Minimum offset to pallet edge:

As explained above, this value establishes a safety margin and ensures that the setting down point of bundled bars does not lie outside the pallet.

![]() 'Sequence' tab

'Sequence' tab

Panel number:

Cross shutter section:

x coordinate:

y coordinate:

Diameter:

Length:

Angle:

Bar type:

Mesh number:

Free bars:

You can enter ranking numbers to set the sequence for the longitudinal bars.

Bandwidth for x and y coordinates:

Where there are very small differences (e.g., at sloping edges), you can enter a range within which sequencing by coordinates is disabled and you can use other sequencing parameters.

![]() 'Sequence no.' tab

'Sequence no.' tab

Bottom cross bars layer 1:

Bottom cross bars layer 2:

Bottom longitudinal bars layer 1:

Bottom longitudinal bars layer 2:

Bottom longitudinal bars layer 3:

Bottom secondary bars in span direction:

Bottom secondary bars transverse to span direction:

Top cross bars layer 1:

Top cross bars layer 2:

Top longitudinal bars layer 1:

Top longitudinal bars layer 2:

Top secondary bars in span direction:

Top secondary bars transverse to span direction:

If the bars are to be sequenced according to bar type, you can enter which bar type has priority here by assigning a ranking number. "Bottom" reinforcement applies to all the reinforcement used in slabs, wall elements and to the bottom reinforcement in hollow plank units. ”Top” reinforcement and top longitudinal bars layer 3 apply to hollow plank units only.

| (C) Allplan GmbH | Privacy policy |